Heat sinks play a critical role in electronic devices by dissipating heat and preventing overheating. Without them, our devices would be at risk of damage or even complete failure. But have you ever stopped to wonder how they’re made?

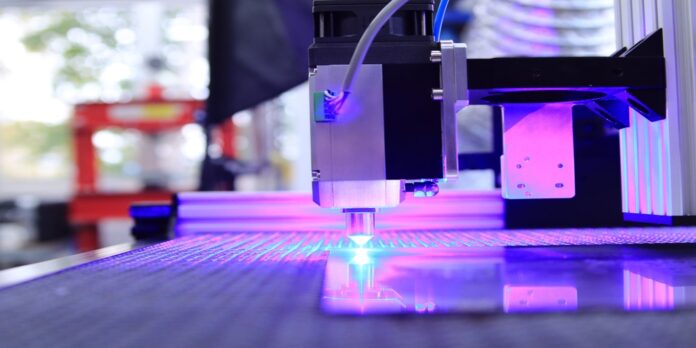

The manufacturing process for heat sinks involves various techniques and technologies, from selecting the right materials to ensure optimal thermal conductivity to utilizing advanced fabrication methods to create intricate designs.

In this article, we’ll look closer at the world of heat sink manufacturing, exploring the different materials used, the techniques employed, and more. So, join us on this journey as we explore the fascinating world of heat sink manufacturing.

Raw Materials Used in Heat Sink Manufacturing

The raw materials used in heat sink manufacturing play a crucial role in determining the performance and durability of the final product. Aluminum is the most commonly used material due to its excellent thermal conductivity and lightweight properties.

Other materials used include copper, brass, and various alloys. In extruded heatsink manufacturing, aluminum billets are heated and forced through a die to create the desired shape. As a result, aluminum extrusion heat sinks are formed.

On the other hand, copper and brass heatsinks are typically machined from solid blocks, making them more expensive to produce but also providing superior thermal conductivity. That’s why manufacturers carefully consider factors like thermal conductivity, weight, and cost when selecting materials for their heatsinks.

Heat Sink Fabrication Techniques

Heat sink fabrication techniques are critical in determining the final product’s performance and capabilities. The process of making a heat sink involves several steps, including extrusion, die casting, stamping, skiving, and forging. Let’s take a closer look at each of these techniques:

Extrusion

This is the most common heat sink fabrication technique. It involves pushing an aluminum billet through a die to create the desired shape.

Die Casting

This technique is used for creating complex heat sinks with intricate shapes. It involves injecting molten metal into a mold under high pressure.

Stamping

This technique is used to create heat sinks with specific designs or shapes. It involves pressing metal sheets into a mold with a hydraulic press.

Skiving

This technique involves cutting thin, parallel fins into a block of aluminum or copper using a special machine. It’s commonly used for creating high-performance heat sinks.

Forging

This technique is used for creating high-strength heat sinks. It involves compressing metal under high pressure to create a solid block of material.

Each heat sink fabrication technique has unique advantages and disadvantages, and manufacturers carefully select the technique that best suits their design requirements and budget constraints.

The Importance of Quality Control in Heat Sink Manufacturing

Quality control is essential in heat sink manufacturing to ensure the final product meets the required specifications and standards. A single flaw in the design or production process can lead to significant performance issues, including inadequate cooling or thermal dissipation.

To ensure optimal performance and avoid issues, heat sink manufacturers like Kingka implement a strict quality control process that tests thermal performance, dimensional accuracy, and overall quality.

By prioritizing quality control, manufacturers can ensure that their heat sinks meet the highest performance and reliability standards, providing customers with a superior product that meets their needs.

Conclusion

In summary, heat sink manufacturing involves a range of raw materials, fabrication techniques, and quality control measures that work together to create a high-performance product that can effectively manage heat dissipation.

Whether it’s an extruded heat sink or another type, investing in a high-quality product can lead to improved performance, increased reliability, and overall satisfaction.