Over the past ten years, steel injection molding (MIM) has mounted itself as an aggressive manufacturing system for small, precise components that would be expensive to make using opportunity techniques. By using steel injection molding (MIM) technology, many issues that exist nowadays can be resolved.

Internet-fashioned elements are perfect for high overall performance, high density, high energy, and high corrosion resistance applications. To know more about the MIM Visit the link https://www.3erp.com/services/injection-molding/metal-injection-molding/. Optimism uses the injection molding technique to supply these components, which sets the standard for the enterprise in phrases of mechanical and bodily attributes. To create a successful venture while designing for MIM, there are more than a few things that need to be explored.

What Is The Typical MIM Production Rate?

A few thousand to numerous million components in line with are normally produced with the use of MIM, which is perfectly suited for medium to high production degrees. Due to the economies of scale attained by using multi-cavity molds and the precise usage of uncooked substances, the method is value-powerful for big volumes. However, because of the unreasonably high initial expenses associated with tooling and process development, MIM might not be an excellent alternative for low production numbers.

Main Elements That Influence the MIM Component Quality

For the high-precision manufacturing of plastic and steel elements, injection molding is a commonly utilized manufacturing process. Numerous factors can also affect the fine of the molded elements. Injection molding is encouraged with the aid of the subsequent 5 principal factors:

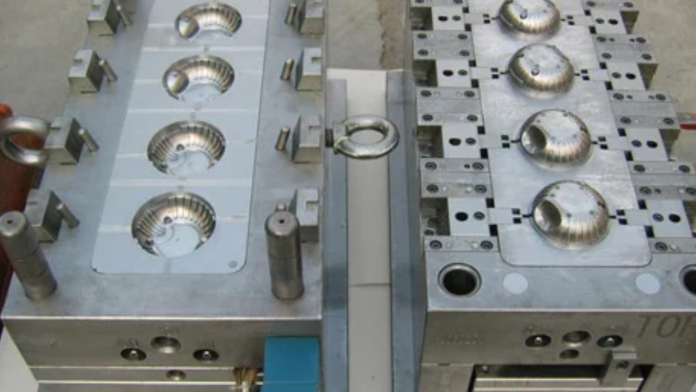

Design of the Mold

The form of the intended plastic product is decided by using the mildew tooling element in injection molding. Commonly, top-class metals like metal or aluminum are used to assemble this component of the machine. To acquire a seamless injection molding technique, all the components and factors of the mold tooling must be in exact working order.

Mildew design is sizeable because it influences how long the producer can depend upon it, that’s another reason. In high-cavitation or high-extent injection molding merchandise, for example, metallic molds may be hired without compromising the durability of every plastic cloth once it has been ejected from the system.

Thickness of the Product Walls

Commonly, injection molding strategies can produce walls with a thickness of 2 to four mm. But, this can depend on whether or not the completed product might be implemented in sectors that demand outstanding dimensional accuracy, along with the scientific, automotive, construction, and similar industries. The fine of the plastic product is frequently better the greater homogeneous the wall thickness is. Regardless of how regularly the producer adjusts temperature, pressure, and float rate, skinny-walled molds can be challenging to fill.

Runner Presence

Typically, runners are carved onto the molding part of an injection molding machine to make it simpler for molten plastic resin pellets to flow into the mold. Whilst warm runners and cold runners are two separate sorts of runners that you can come upon, an effective injection molding technique gets rid of this element completely.

Hot runner structures, despite their name, do not require using runners to transmit the glide of molten resin. That is because numerous chambers and holes permit the resin to be heated continuously all through the system. This era substantially reduces lead/cycle instances as well as any submit-production techniques for removing undesired additives because it does away with runners.

Surface Finishing

The molding factor’s surface completion, further to its dimensional high quality, impacts the exceptional of the ejected end result. There are numerous floor completing sorts, which include semi-gloss, matte, glossy, and stone-like. In lots of aspects, the tooling material’s surface completion determines how properly the injection-molded plastic can manage subsequent secondary operations like coating. This is a crucial thing to remember, especially while the plastic product desires to have adaptable designs. For example, adding texture to the plastic with a stone-like sharpening will make it less complicated for paint to paste to it.

Raw Materials

Finally, the high quality of injection molding also can be impacted by uncooked substances. The maximum popular resins applied in this production manner encompass polystyrene, ABS, polycarbonate, and polypropylene, however not all of those substances can be the perfect option for every utility.

As an example, high-density polyethylene can be used to create not unusual plastic goods like toys, food bins, and bottles. Evaluation of this with polycarbonate, which is more applicable for excessive-impact and structural packages inclusive of sporting goods, construction panels, and limitations.

Lastly,

You presently recognize a variety of factors that impact the pleasantness of injection molding from this tutorial. Raw materials, mold layout, mildew surface finishing, wall thickness, and the presence of runners are those. All of those elements can have an impact on whether you receive a material of exquisite first-rate that can be applied for the meant purpose.